Technik und Montage: Zweischalig wärmegedämmter, nicht belüfteter Dachaufbau

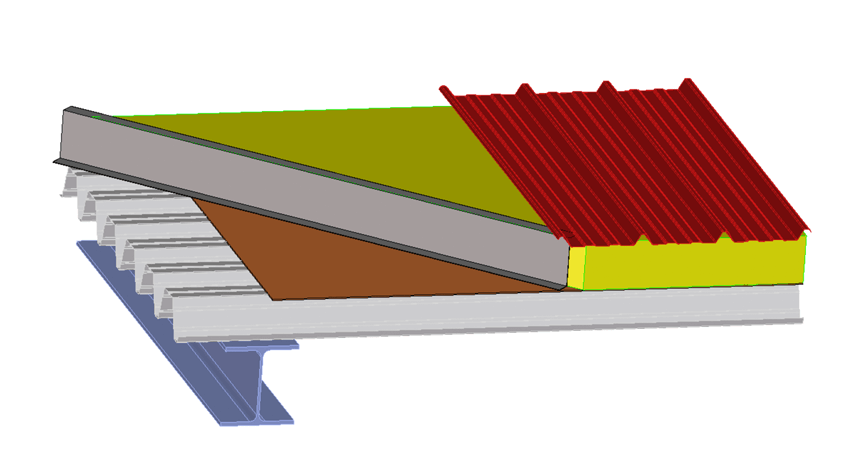

Zweischalige und wärmegedämmte Dachaufbauten bestehen aus einer tragenden Unterschale aus Trapezprofilen, dem Wärme- und Feuchteschutzpaket, einer Distanzkonstruktion und Trapezprofilen an der Dachoberseite als Wetterschutz. Die Distanzkonstruktion besteht meistens aus gekanteten Z-Profilen aus verzinkten bzw. verzinkt/beschichteten Stahlblechen oder seltener aus einer Holzkonstruktion. Holzkonstruktionen müssen mit dem erforderlichen Feuchte- und Insektenschutz behandelt worden sein.

Bei den nicht belüfteten Dachaufbauten ist zwischen Dämmung und dem Trapezprofil an der Dachoberseite keine belüftete Ebene angeordnet.

Bei größeren Dämmstoffdicken sind die Dämmstoffe zweilagig im Versatz zu verlegen. Damit keine Hohlräume zwischen Dämmstoff und Dachprofil entstehen, wird die Dämmstoffdicke um 20mm höher gewählt. Beim Auflegen der Dachtrapezprofile wird dann die Dämmung komprimiert. Dies verhindert ein Vagabundieren eingedrungener Luft in den Dachaufbau.

Wärmebrücken zwischen Dachoberschale und der Distanzkonstruktionen werden mit geeigneten thermischen Trennstreifen aus Faserverbundmaterial oder Kunststoff minimiert. Gegebenenfalls kann die Distanzkonstruktion auch 2-lagig erfolgen. Die Distanzkonstruktion wird in der Regel diagonal verlegt.

Der Dachaufbausetzt setzt sich von außen nach innen wie folgt zusammen:- Dachoberschale mit Trapezprofil

- Wärmedämmung und Distanzkonstruktion mit therm. Trennung

- Dampfsperre

- Tragende Dachunterschale aus Trapezprofil